The hard life of crash test dummies

Crash test dummies have a tough life. But their work helps save lives. Find out what they are and what they have to go through.

While computer simulation tools are playing an increasingly important role in new car development, crash tests aren’t on the way out. That is why Škoda has its own extensive crash laboratory, where it tests the safety of cars in practice and under strictly defined conditions on an almost daily basis (up to 300 crash tests are carried out here per year).

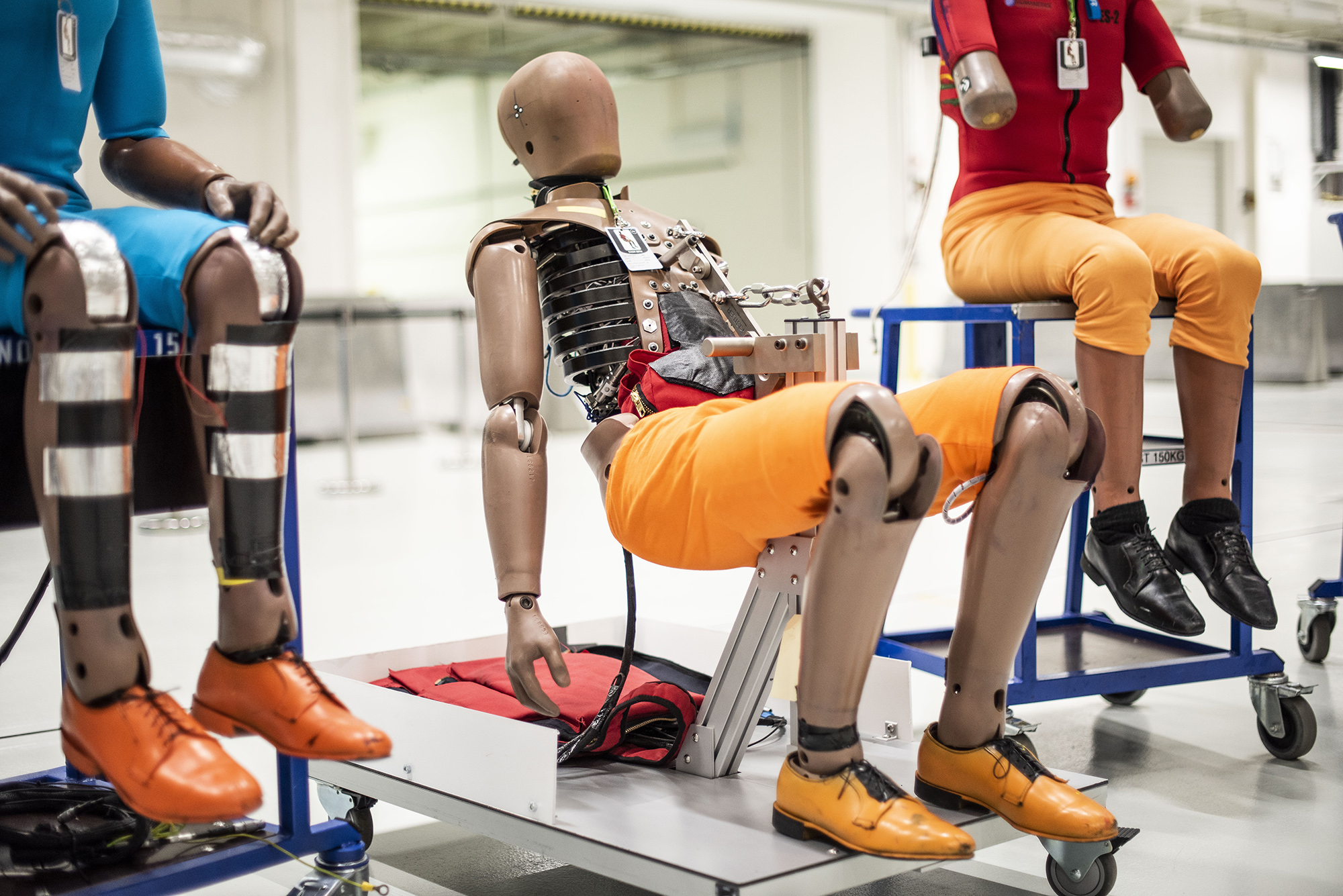

Every dummy is fitted with dozens of sensors and measuring points.

Every dummy is fitted with dozens of sensors and measuring points.

In addition to obstacles, lights, cameras and lots of different sensors, crash test dummies are an essential actor in car safety testing. And the fact that crash tests are becoming more and more stringent and demanding is evidenced, among other things, by the fact that the number of types of crash dummies used by Škoda is on the rise. While only a few types of dummies were previously required, the Czech carmaker now uses at least twelve. There are eight types of adult passenger dummies alone. And then there are child dummies, representing children aged 1.5, 3, 6 and 10.

Child dummies range in age from 1.5 years to 3, 6 and 10.

Child dummies range in age from 1.5 years to 3, 6 and 10.

Why so many? Because safety needs to be tested in a variety of situations and with different types of passengers. “In crash tests, different types of dummies are used to represent the various human genders and sizes. Male, female and child dummies are used in crash tests. The size and design of the dummies is based on the requirements of individual homologation regulations, consumer tests and internal requirements based on population distribution,” explains Jan Domkář, coordinator of vehicle safety development, adding that each type of dummy reacts differently in a particular test and interacts differently with the vehicle’s restraint systems and design. And that is the goal: to test as many options as possible to ensure that both adult passengers and children are well protected, wherever they sit in the car.

Jan Domkář

Jan Domkář

car safety development coordinator

50% male, 5% female

In addition, a slightly different dummy is suitable for each type of test. These are specially designed to best simulate the behaviour of the human body for a particular test. “For frontal impacts, dummies such as Hybrid III or Thor are used, while for lateral impacts we use EuroSID II and WorldSID dummies,” Domkář explains.

Inflatable dummies are also used in car development tests.

Inflatable dummies are also used in car development tests.

Dummies often have a percentage marking, for example 50% male. All that means, though, is that this is an average male in terms of height and weight. For women, the most common dummy is “5% female”, which means that only 5% of women are physically smaller than the dummy.

As Jan Domkář explains, only standardised dummies are used in the tests. This is based on the requirement of homologation tests and more stringent consumer tests carried out according to the EuroNCAP methodology, for example. The same dummies are used in both official tests and internal ones, which are performed by the company to verify safety during the development of a car before it is confirmed by official testing.

Metal ribs and spine, plastic skin

Dummies are always made from a wide range of materials. The basic metal construction is strong and durable, but the dummy’s body is also made up of materials that simulate the behaviour of the human body in specific situations as faithfully as possible. Special metals are thus used for the ribs, spine or joints, while the dummy’s skin or pelvis is made of specific plastics. The loads on these parts are measured, making it possible to deduce where and what the actual injuries are likely to be. The individual parts are replaceable, of course, so the basic dummy is reusable and has an essentially unlimited lifetime.

There are eight types of adult dummy used by Škoda.

There are eight types of adult dummy used by Škoda.

Many of the design elements of the dummies are patented and only a few manufacturers in the world produce dummies to the highest standard. As a result, it is logical that dummies are expensive – in fact, they are often the most expensive piece of equipment used in a crash test. “For example, the Thor frontal dummy costs 650,000 euros and the WorldSID side impact dummy 350,000 euros. On top of that you have to add the considerable costs of servicing and calibration,” explains Domkář. In addition, calibration is carried out after a prescribed number of tests or when biomechanical limits are exceeded.

Something new all the time

Each dummy is then fitted with dozens of sensors that measure acceleration, forces and deformation. Moreover, all this technology is constantly evolving. While the 50% male dummy (Hybrid III) used at the turn of the millennium allowed measurements at 56 points on the body, the current THOR dummy has 116 measurement locations. Similarly, the EuroSID2 dummy with 57 measuring points used to be widely used for side impact testing, but today it is getting squeezed out by the WorldSID dummy with 94 measuring locations. WorldSID also has a significantly better similarity to the human body, rated at 7.6/10, compared to 4.6/10 for the older dummy.

Modern cars are put through increasingly sophisticated testing.

Modern cars are put through increasingly sophisticated testing.

In addition to greater human similarity and a greater number of sensors, new types of dummies appear in the tests from time to time. “Work is currently taking place on Thor and WorldSID dummies that will represent 5% women. Another trend in dummies is towards reflecting the more advanced age of car occupants,” Domkář says, pointing out where innovations in this area can be expected.